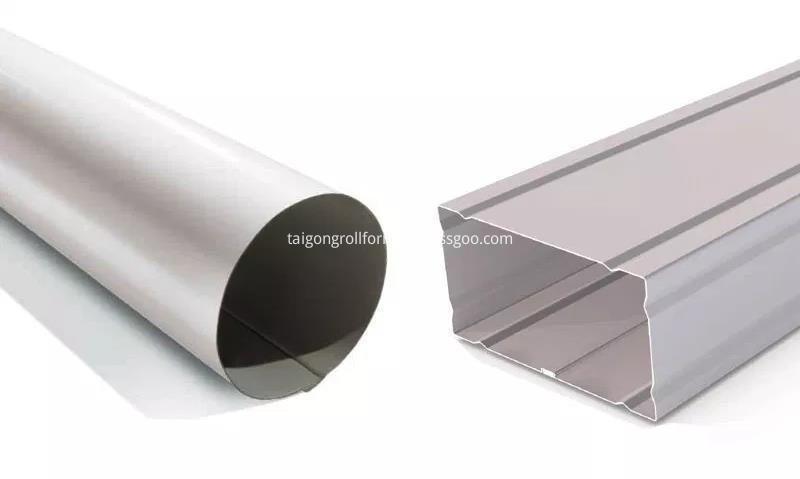

Light Pipe Downspout Roll Forming Machine

Basic Info

Model No.: TG-0274

Product Description

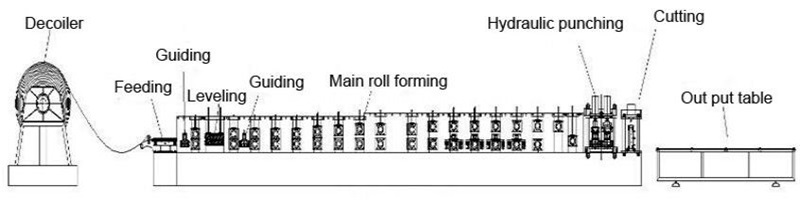

This kind of Downspout Roll Forming Machine mainly consists of decoiler, Roll forming system, cutting equipment, hydraulic system, PLC control system, Run out table. And the curving pipe forming machine is the complementary. Rain Downpipe Making Machine Equirement for this kind of Round Downspout Machine, which can make curve for down pipe to meet the requirement of practical engineering projects. The product of Steel Downspout Pipe Forming Machine is more durable than the tranditional ppc pipe, and not easy to aging. Downpipe Roll Forming Machine will make the project more integrate, and help enhancing the image of all project. Downspout Pipe Making Machine used for bend the roll formed pipe, to connect the drainpipe and the elbowed pipe.

2. The Chart of Process flow

Manual de-coiler --- Electric Feeding --- Servo motor feeding ---- Roll Forming Machine------ Computer Control Cabinet--- Automatic cutting Mechanism --- Run-out Tables

3. The equipment including

| Roll forming machine | 1 set |

| Hydraulic cutter | 1 set |

| Electrical control system | 1 set |

| Hydraulic system | 1 set |

| Normal run out table | 1 PC 1m*1m |

| Manual de-coiler | 1 set Max. loading 5 T |

4. Technical specification and details

(1) Hydraulic Ue-coiler

Un-power: manual de-coiler; Max. Capacity: 7T

Suit for coil inner diameter: 508mm, suitable coil Max. out diameter: 1000mm

Manual power expands the coil inner surface.

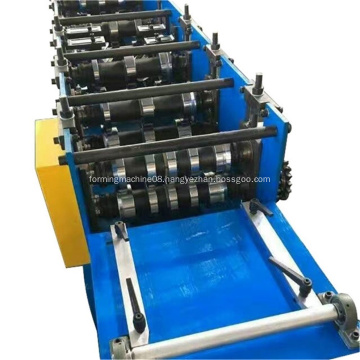

(2) Steel Tube Downpipe Forming Machine

No. Main parameter of Steel Tube Roll Forming Machine 1 Suitable to process Color steel plate 2 Width of the plate 330mm 3 Rollers 15rows 4 Dimensions 7400*1150*1510mm 5 Power 5.5+4kw 6 Rolling material high grade 45# steel(plated chrome on surface) 6 Thickness of the plate 0.3-0.6mm 7 Productivity 8-10m/min 8 Diameter of the roller Φ66mm 9 Voltage 380V 50Hz 3phases 10 Material of the cutting plate Cr12 11 Hydraulic 40# 12 Processing precision Within 1.00mm 13 Control system PLC control

(3) Hydraulic Cutting

1) Adopts post cutting, Stop to cut;

2) The cutting blade material is Cr12 with quenched treatment.

3) Adopts welded frame for good rigidity.

4) Cutting frame has been heat treatment to avoid final product deformation. cutting length tolerance ±2mm.

5) The power of cutting is provided by hydraulic station.

6) The final product can be cut as per set length in PLC controller, and the length is automatically measured by encoder. When final product reaches the set length, machine will stop to cut the Product automatically. Finish this action, machine will run again continuously.

(4) Hydraulic station

1) It supplies the power for the hydraulic cutter.

2) All hydraulic accessories are all use Chinese famous brand products.

3) Hydraulic motor power: 3KW

(5) PLC Control System

1) This system uses Delta PLC to control the all working actions. Production quantity and each piece length will be automatically measured. It is convenient to control the Downpipe Roll Forming Machine.

2) Delta converter adjusts speed technology, realize the automatic production.

3) Text screen is input and cancelled the working data.

4) Friendly man-machine interface system can be set batches to the work piece, length, quantity, etc.

5) Encoder count, having function of count and measuring length.

6) Suitable power voltage: 380V/50HZ/3Phase (can de designed according to buyer`s requirement)

(6) Product Rack ( un-powered)

1) They are used to put the final product when product coming out from cutting device.

2) Two pieces, each piece length is 1m, total length is 3 meters.

3) Collect the final product and final products are convenient to be stacked by workers.

5. Equipment for Reference

6. Scene application

7. Customer

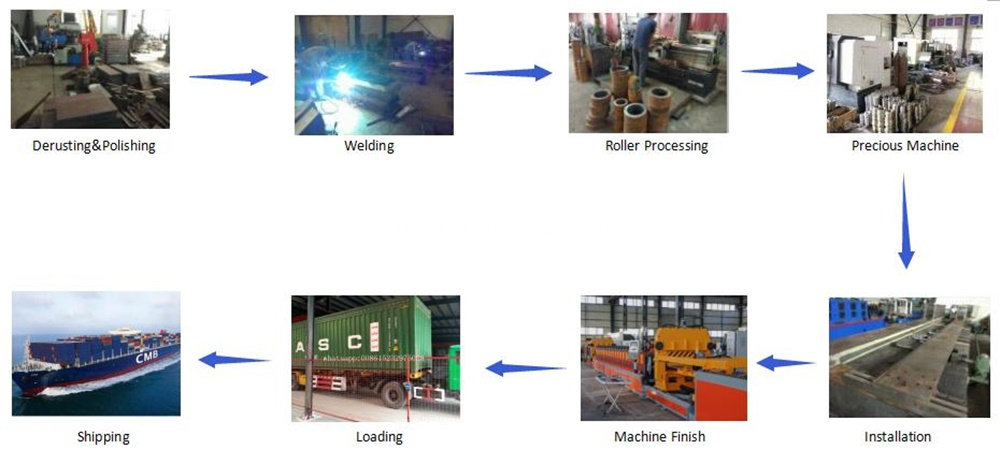

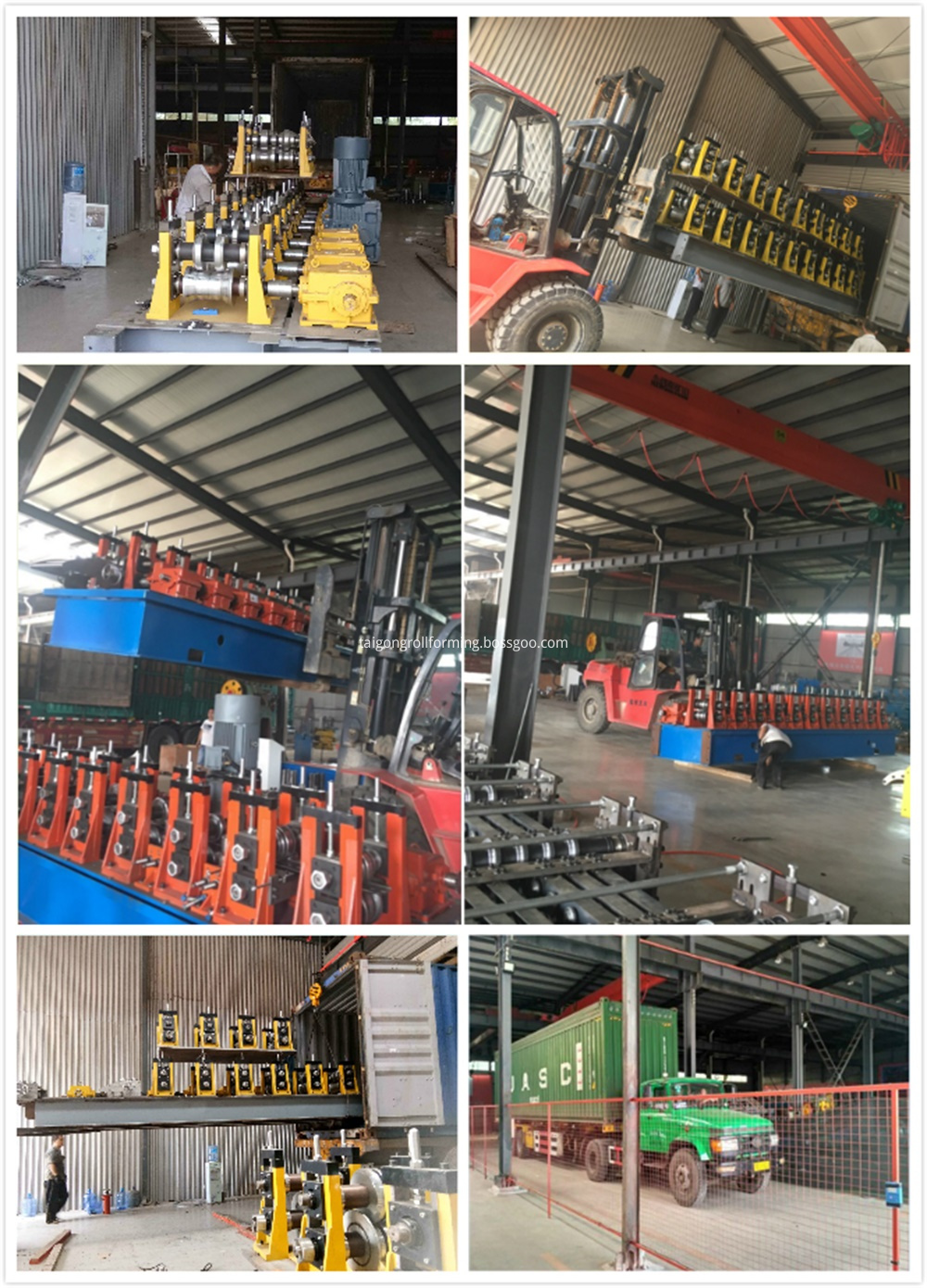

8. Loading

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping Downpipe Machine

3) Delivery time: 45-50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping Rain Pipe Forming Machine cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

6) Installation and training:

1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual or video to teach you to install and operate Automatic Gutter Machine

3. COST OF INSTALLATION:

The buyer should pay the installation charges (USD 100 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Hebei Taigong Roll Forming Machinery Co., Ltd. have been specialized in Channel Machine manufacture for many years. Our main products are various kinds of highway guardrail roll forming Machine,Silo Machine,Spiral Corrugated Pipe Machine,Grain Bin Silo Machine,Purlin Roll Forming Machine,Metal Culvert Pipe Machine,Rib Lath Machine, etc. Welcome to do business with us. If you have any further question of our Roll Forming Machinery include Steel Downpipe Cold Roll Forming Machine, please feel free to contact me.

Product Categories : Drainage System Roll Forming Machine > Round Downpipe Roll Forming Machine